Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Electric tools are devices that convert electrical energy into mechanical energy, exerting force on components through rotational motion. Common electric tools include electric drills, angle grinders, impact wrenches, electric screwdrivers, rotary hammers, impact drills, concrete vibrators, electric planers, etc. Currently, to ensure smooth operation, most handheld electric tools powered by lithium battery packs use brushless motors instead of brushed motors.

So why choose brushless motors for electric tools?

Brushless motors are the core of electric tools. Since electric tools experience varying loads and speeds during operation and require good torque output at both high and low speeds, most brushless motors adopt Hall effect control. The controller determines the rotor position of the motor through feedback from Hall sensors, thereby controlling the continuous operation of the motor.

Brushless motors eliminate the need for brush commutation mechanisms, offering advantages such as low cost, long lifespan, and high reliability in engineering applications. Additionally, compared to brushed and brushless motors, brushless motors improve motor power utilization and reduce failure and maintenance costs.

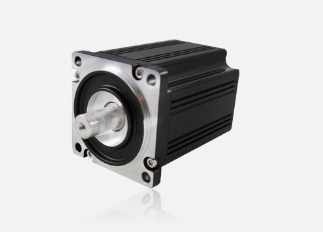

To achieve high torque in electric tool applications, we offer the BLDC60+G motor and gearbox design solution. The motor has an outer diameter of 60mm, voltage ranging from 18 to 220V, power from 100 to 800W, speed from 3000 to 10000rpm (without reduction), a reduction ratio of 1:4.3 (customizable), and an external drive.