Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Electric tools, powered by electric motors or electromagnetic force through transmission structures, are handheld or portable mechanized tools used for various tasks due to their lightweight structure and convenient portability. They are widely used in various sectors of the economy and in daily households. Meanwhile, safety issues regarding electric tools have received widespread attention.

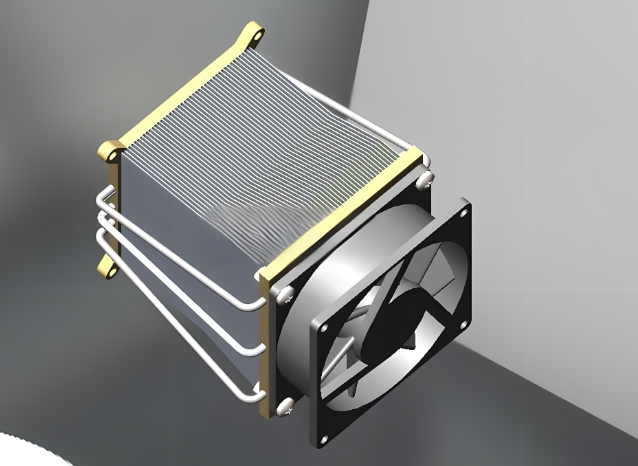

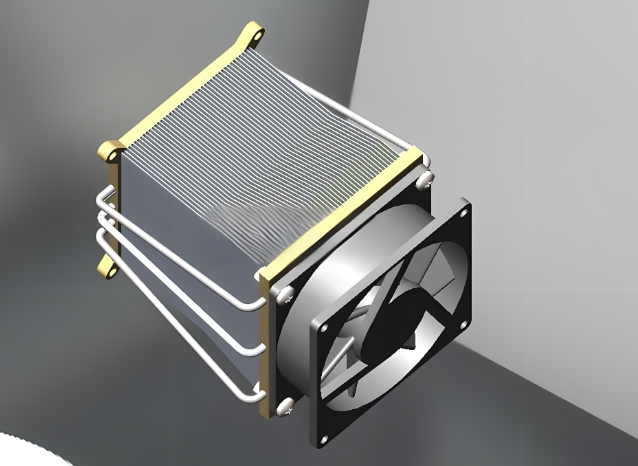

Heat generation is a crucial aspect of safety assessment for electric tools. Electric tools consist of components such as casing, electric motor, transmission mechanism, working head, handle, power switch, and power connection components, among which the electric motor is the core part. During operation, the motor generates losses, impacting its efficiency and causing heat buildup. If the motor temperature rises too high during operation, insulation materials may age faster, leading to decreased insulation performance and even motor burnout. Therefore, heat generation directly affects the service life and reliability of the motor.

As electronic products become increasingly intelligent and diverse, with higher demands for performance and safety, the demand for electronic components such as motor drive chips and controller chips in electric tools is also increasing. This leads to numerous heat dissipation issues. Therefore, manufacturers recommend the use of TIG780-56 Thermal Conductive Silicone Grease with a thermal conductivity of 5.6W/mk and TIF600GP High Thermal Conductive Gap Pad with a thermal conductivity of 6.0W/mk to help efficiently transfer heat. Both are non-toxic and environmentally friendly thermal conductive products. Their excellent performance facilitates the transfer of heat from heat-generating components or the entire PCB to metal casings or heat sinks, thereby improving the efficiency and service life of heat-generating electronic components and solving overheating and reliability issues. They are widely used in power electronics, CPUs, LEDs, electrical equipment, and 5G communications.”