Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Talk about brushless DC motors in power tools

Power tools have come a long way over the past century. Today, they are cordless, lightweight, battery-powered and powerful, taking over a lot of our work. So, what’s driving power tools? Outside of power tool enthusiasts, a lot of it has to do with the many advancements in semiconductor technology — especially when it comes to cordless power tools.

This blog covers the key features of cordless, battery-powered products, including the factors driving their continued evolution and the many challenges along the way; and how microprocessors and brushless DC motors are changing the power tools we use today. played an important role. In addition, the article also discusses the introduction of brushless DC motors in power tools and what competitive advantages it brings to manufacturers.

Main components of power tools

The first component of a power tool is the power supply. All power tools can be divided into two broad categories: corded and cordless.

Corded Tools – The power source is AC and needs to be plugged into a “wall” socket to operate.

Cordless tools – rely on electricity stored in batteries with different chemistries, such as nickel cadmium (NiCd), nickel metal hydride (NiMH), and lithium ion (Li-Ion).

Lithium-ion batteries have become the most outstanding battery type due to their enhanced energy density and flexibility in maintaining charge.

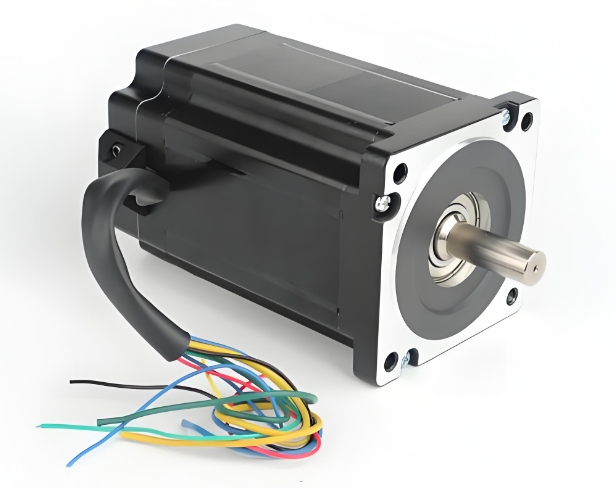

The second component is the actuator, or the motor that converts electrical energy into mechanical energy. This motor can be a general AC/DC brush motor, a DC brush motor, or a brushless DC (BLDC) motor. Many of today’s tools have moved to three-phase BLDC motor topologies.

Finally, a switch is used to control the transfer of energy from the power supply to the motor. This component can be a simple interrupter that controls whether current flows, or a slightly more complex device such as a potentiometer that allows the user to specify how much energy flows from the power supply to the motor.

The challenge of power tools

In the first 100 years of the development of power tools, designing and manufacturing drills, sanders, grinders, screwdrivers, hair dryers, saws and other tools required only a power supply, a motor and a switch/potentiometer. However, in the 20th century, the advent of high-energy-density batteries changed this. Additionally, we are seeing the emergence of green energy solutions and a trend towards incorporating them into all design forms.

The challenge is how to continue to use a potentiometer to control the speed of the tool without having to pass high current through its resistive component. As we’ll see later, this is a fairly simple restorative move. The electric motor, on the other hand, proved to be a more substantial and complex challenge.

In the early days of power tools, the motors used were either brushed universal AC/DC motors for corded tools or brushed DC motors for cordless tools, as shown in the figure below. Since the essential topology of these two motors is a brushed motor, current is transmitted to the copper commutator through carbon brushes, which then generates an internal rotating magnetic field to obtain motion. Placing the electromagnet windings and the commutator on the rotor, and placing the permanent magnets on the stator, we can obtain two magnetic fields that constantly interact, thereby achieving the motion we need.

Unfortunately, this comes at the expense of a lot of friction between the brushes and commutator. The friction is quite severe, and after long-term use, the motor will damage itself; the energy generated by friction is eventually wasted in the form of heat. The source of this energy comes from the power source, but it does not produce any useful work. Statistically, systems around this topology are less than 80% efficient (in the best case scenario); this means that 20% of the energy inside the battery is used to generate heat.

When you’re trying to drill a hole with a battery-powered drill, using 1/5 of the power to generate heat doesn’t sound very appealing.

Addressing challenges with BLDC motor topology

Given the various challenges discussed above, it is obvious that replacing or removing the brushes and commutator is critical. This is even more prominent in the three-phase BLDC motor topology, as shown in the figure below. A BLDC motor gives us the exact same rotational motion without the use of brushes or a mechanical commutator; instead, we generate the rotating magnetic field electronically. With electronic circuits, we can create two interacting magnetic fields to drive motor movement. The advantage of this is that friction between the rotor and stator components is eliminated, thereby increasing reliability and energy efficiency.

The efficiency of three-phase brushless DC motors can be as high as 96%. This means our batteries only waste 1/20th of their power in the form of heat.

As with all designs, there are some challenges when using BLDC motors. Brushed DC motors solve the inherent problem of aligning two magnetic fields for the most efficient motion profile. This is achieved when the commutator sequence is designed and placed in such a way that the rotating magnetic field is always aligned with the magnetic field of the permanent magnets. However, since BLDC motors do not have a physical commutator, this action is accomplished through a logical sequence of commutation. To achieve the efficiency mentioned earlier, we must align the two magnetic fields as perfectly as possible using a control circuit like the one shown below.

Such complex circuits extract the position of the rotor and electronically align the two magnetic fields. For three-phase BLDC motors, this module usually consists of a microcontroller and a three-phase inverter power stage that uses sensor devices such as Hall sensors to obtain rotor position information. Adding this circuit does take up some space and adds some cost. However, manufacturers are noticing the benefits of freedom from tethering, and consumers are creating demand for these types of motor solutions. Therefore, an increasing number of power tool designs are based on three-phase BLDC motor topologies.

Complex power tools

Modern power tools still consist of a power supply, a motor actuator, and a device that controls the flow of energy (such as a potentiometer). However, to provide all the energy conservation features, we need to add smart technology to it.

This intelligence is provided by the microprocessor. With a microprocessor we can now monitor the power supply and provide the required drive. We can also monitor the value of the potentiometer and control the speed of the motor without passing current through its resistive element. We achieve this with an analog-to-digital converter (ADC), and the energy consumption in the process is negligible.

Regardless, the most important role of the microprocessor is to build an efficient mechanism to properly power the three-phase BLDC motor to improve the efficiency required for battery-powered tools. The microcontroller-based power stage provides all the tools to successfully generate a correctly aligned rotating magnetic field and translate it into an optimal motion profile.

Here is a list of items required to implement most modern power tools:

A microprocessor provides intelligence for the energy transfer process from power supply to actuator;

A circuit that drives a power stage switch (field effect transistor – FET) to generate a rotating magnetic field;

A circuit that extracts the position of the motor rotor so that we can correctly align the rotating magnetic field;

An ADC to monitor battery voltage and current, motor current, potentiometer status, and system temperature;

Protective circuitry to ensure reliable system operation without endangering the user or tool;

Circuits that monitor different signals, such as switches that define the direction of motor rotation;

Different voltage regulators power the above circuits;

From switches and motors to the list above, it’s obvious that the size of our circuit has increased significantly. However, new technology allows us to fit all of this into a small form factor, which is another key factor why motor manufacturers favor BLDC topologies.

PAC5xxx series devices: single package, small size solution

Qorvo’s solution, the PAC5xxx family of devices, provides all the benefits of motor functionality while taking up minimal space. Devices like the PAC5527 integrate the circuitry required to drive most battery-operated power tools in a single, extremely small footprint.

The PAC5527 contains a DC/DC converter that takes the battery voltage and steps it down to different voltage rails to power different modules of the system. The device includes three high-current pre-driver stages required to drive a very powerful three-phase inverter (over 1 KW); its ADC has a programmable sequencer to coordinate the capture of multiple analog parameters without affecting the central Processor (CPU) real-time performance. It also contains protective blocks to ensure that the system current remains within certain limits, preventing dangerous conditions that could result in damage to the tool while keeping the user safe from harm such as fire. The product also provides multiple general purpose input/outputs (GPIO) to monitor different signals; circuitry to extract rotor position information allows us to generate a fully aligned rotating magnetic field, thus completing a library of tools packaged in a single PAC5527 device part.

PAC5527 creates one of the smallest three-phase inverter power drivers. With such a compact solution, power tools can be designed according to ergonomic principles while increasing energy efficiency. In addition, due to its small footprint and high integration level, the cost structure of the entire application is also optimized.

The next wave of power tools

The manufacturing and application of BLDC motors are accelerating. With the continuous evolution of technology, these motors will become more user-friendly, efficient and reliable. Thanks to the advent of electronically controlled BLDC motors, tools have become more powerful, more efficient, smaller and lighter. Over time, Qorvo will continue to introduce innovative products like the PAC5xxx family of devices that push three-phase BLDC motor topologies even further.