electric hand drill drawing?

Introduction

Electric hand drills are versatile and indispensable tools used in various applications ranging from household tasks to professional construction work. This guide will provide an overview of the common types of electric hand drills, their features, and typical uses.

Types of Electric Hand Drills

- Corded Drills

- Standard Corded Drill

- Hammer Drill

- Rotary Drill

- Cordless Drills

- Standard Cordless Drill

- Hammer Drill

- Impact Driver

- Right-Angle Drill

Features and Specifications

- Motor Power

- Speed Control

- Chuck Size and Type

- Battery Life and Charging

- Additional Features

Common Uses of Electric Hand Drills

- Home Improvement Projects

- Construction and Renovation

- Automotive Repairs

- Woodworking and Metalworking

Conclusion

Summarize the importance and utility of electric hand drills in various fields.

Introduction

Electric hand drills are among the most essential tools in any toolkit, prized for their versatility and efficiency. From driving screws to drilling holes in various materials, these drills have revolutionized DIY and professional work environments. This guide aims to introduce the most common types of electric hand drills, highlighting their features, specifications, and common uses.

Types of Electric Hand Drills

Electric hand drills can be broadly categorized into corded and cordless models. Each type has its subtypes designed for specific tasks.

Corded Drills

- Standard Corded Drill

- Description: The standard corded drill is powered by an electrical outlet, providing consistent power and performance. It is a go-to tool for many household and professional tasks.

- Features: Typically features a variable speed trigger, forward/reverse switch, and a keyless chuck for easy bit changes.

- Uses: Ideal for drilling into wood, metal, and plastic. Suitable for continuous use without the worry of battery life.

- Hammer Drill

- Description: A hammer drill combines rotary drilling with a hammering action, making it suitable for masonry work.

- Features: Includes a hammer function that can be toggled on or off. It also has variable speed settings and a more robust build to handle tough materials.

- Uses: Perfect for drilling into concrete, brick, and stone. Not recommended for delicate tasks due to its high-impact action.

- Rotary Drill

- Description: Rotary drills, also known as rotary hammers, are heavy-duty tools designed for demanding drilling and chiseling tasks.

- Features: They have a piston mechanism that delivers a powerful hammering action. Often come with multiple modes including drill, hammer, and chisel.

- Uses: Best for large-scale construction projects, such as drilling large holes in concrete or breaking up asphalt.

Cordless Drills

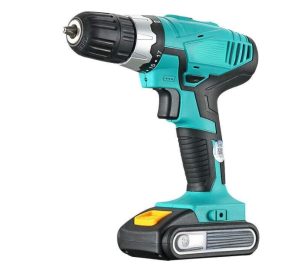

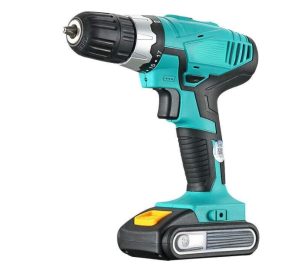

- Standard Cordless Drill

- Description: These drills offer the convenience of portability, powered by rechargeable batteries.

- Features: Usually come with a variable speed trigger, forward/reverse control, and a keyless chuck. Batteries vary in voltage, commonly ranging from 12V to 20V.

- Uses: Suitable for a wide range of tasks including drilling and screw driving. Ideal for locations without easy access to electrical outlets.

- Cordless Hammer Drill

- Description: Similar to the corded hammer drill but powered by batteries.

- Features: Combines the functionality of a standard drill with a hammer mechanism. Offers the same convenience and portability as other cordless models.

- Uses: Excellent for masonry work in areas where a corded drill would be impractical.

- Impact Driver

- Description: Designed primarily for driving screws and bolts with high torque.

- Features: Uses a combination of rotational force and concussive blows to drive screws more efficiently than standard drills. Compact and lightweight design.

- Uses: Perfect for tasks that require driving long screws or bolts, such as assembling furniture or decking.

- Right-Angle Drill

- Description: Features a head that is set at a right angle to the body, allowing it to fit into tight spaces.

- Features: Compact design with variable speed control. Often used in electrical and plumbing work.

- Uses: Ideal for drilling in confined areas like between joists or inside cabinets.

Features and Specifications

- Motor Power

- The power of a drill’s motor is typically measured in watts for corded drills and volts for cordless drills. Higher power ratings indicate a more capable and efficient drill. For example, corded drills often range from 500W to 1000W, while cordless drills range from 12V to 20V or more.

- Speed Control

- Most electric hand drills feature variable speed control, allowing the user to adjust the drilling speed based on the task. This is usually controlled via a trigger mechanism and can range from a few hundred to several thousand RPM (revolutions per minute).

- Chuck Size and Type

- The chuck is the part of the drill that holds the drill bit. Common sizes include 3/8-inch and 1/2-inch, with keyless chucks being the most user-friendly option as they allow for easy bit changes without the need for a chuck key.

- Battery Life and Charging

- For cordless drills, battery life is a crucial factor. Lithium-ion batteries are the most common, known for their long life and quick charging times. Battery capacity is measured in ampere-hours (Ah), with higher values indicating longer battery life.

- Additional Features

- Modern electric hand drills may come with a range of additional features such as built-in LED lights for better visibility, ergonomic handles for improved comfort, and smart chargers that optimize battery life.

Common Uses of Electric Hand Drills

- Home Improvement Projects

- Electric hand drills are indispensable for a variety of home improvement tasks. From assembling furniture to installing shelves and cabinets, these tools make DIY projects easier and more efficient. Cordless drills, in particular, are favored for their portability around the home.

- Construction and Renovation

- In construction and renovation, drills are used for framing, roofing, and electrical installations. Hammer drills and rotary hammers are essential for drilling into concrete and other hard materials, while standard drills are used for wood and metal.

- Automotive Repairs

- Mechanics often use electric hand drills for tasks such as drilling out broken bolts or screws and installing accessories. Impact drivers are particularly useful in automotive work due to their high torque output.

- Woodworking and Metalworking

- In workshops, drills are used for creating precise holes in wood and metal. Right-angle drills can be particularly useful in woodworking for drilling in tight spaces. Drill presses, a stationary form of electric hand drills, provide greater accuracy and stability for detailed work.

Conclusion

Electric hand drills have transformed the way we approach various tasks, making them quicker, easier, and more efficient. Whether you are a DIY enthusiast or a professional tradesperson, understanding the different types of drills and their applications can help you choose the right tool for the job. From the reliable power of corded drills to the flexibility of cordless models, these tools are a staple in modern toolkits, offering a solution for almost every drilling need.