Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Power saws are essential tools in woodworking, enabling users to cut through wood with speed and precision. With various types available, each suited for different tasks, power saws have become indispensable for both professional carpenters and DIY enthusiasts. This report will explore the most effective power saws for woodcutting, discussing leading brands and models that cater to different cutting needs.

Understanding the types of power saws is crucial as each is designed to fulfill specific woodworking needs. Here’s a breakdown:

Several leading brands manufacture power saws, each offering different models with unique features.

DeWalt: Known for its durability and innovative features, DeWalt offers a range of power saws designed for heavy-duty work.

Makita: A leader in cordless saws, Makita is known for producing lightweight and high-performance tools.

Bosch: Bosch produces high-quality power saws that emphasize precision and user comfort, ideal for both professionals and hobbyists.

Milwaukee: Recognized for its powerful and durable saws, Milwaukee tools are designed for demanding woodcutting tasks.

Ryobi: An affordable brand popular among DIYers, Ryobi offers reliable saws with great value for money.

Each type of power saw is highlighted below, with popular models from leading brands and their features.

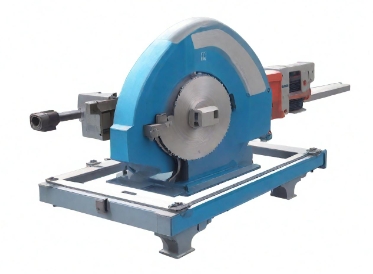

Circular saws are among the most popular for cutting wood due to their power and ease of handling.

Jigsaws are perfect for detailed work, including curved cuts in wood.

Table saws are widely used in woodworking for precise straight cuts and bulk processing.

Ideal for making accurate crosscuts and miters, miter saws are essential for tasks like framing and molding.

Reciprocating saws are typically used for rough cuts or demolition, though they are also useful for quick woodcutting tasks.

Band saws are ideal for curved cuts and can handle thicker wood materials with ease.

Choosing the right saw depends on various factors:

Each type of power saw has its advantages and disadvantages. Circular saws are versatile but may lack the precision of a table saw. Miter saws excel in angled cuts but are not ideal for long rip cuts. Understanding these nuances helps users select the saw that best fits their project requirements.

To ensure longevity and optimal performance, regular maintenance and care of power saws are essential. Below are some key tips to keep in mind when maintaining power saws for cutting wood.

Regular Cleaning

Power saws can accumulate sawdust and debris over time, which can affect the saw’s efficiency. It is important to clean the saw after each use, paying close attention to the blade, motor housing, and air vents. A clean saw will run more efficiently and reduce wear and tear.

Blade Maintenance

The saw blade is a crucial component, and keeping it sharp ensures clean cuts and reduces the strain on the motor. Periodically check for dull or damaged blades and replace them when necessary. Some saws offer easy-to-replace blades, while others may require a bit more effort to install new ones. For circular and jigsaw blades, always make sure they are installed correctly and that the teeth are sharp.

Lubrication

Some power saws, such as band saws and reciprocating saws, may require regular lubrication to ensure smooth operation. Check the manufacturer’s recommendations regarding the type of lubricant to use and how often to apply it.

Checking the Motor and Parts

The motor is the heart of a power saw. Ensure it is running smoothly by checking for any unusual sounds or signs of overheating. For corded saws, inspect the power cord for any damage. Cordless saws should have fully charged batteries, and the battery should be removed when the tool is not in use for extended periods.

Proper Storage

When storing power saws, always ensure they are kept in a dry, cool place. Humidity and exposure to the elements can lead to rust or electrical malfunctions. Storing the saws in their original cases or on a tool shelf can protect them from physical damage.

Today’s power saws come equipped with several advanced features that enhance usability, safety, and cutting performance. Below are some innovative features found in top-tier models:

Brushless Motors

Brushless motors are a recent advancement in power tools, providing more power and longer battery life compared to traditional brushed motors. These motors also generate less heat, reducing wear and tear over time. Brands like Makita, Milwaukee, and DeWalt offer models with brushless motors for increased efficiency.

Electronic Speed Control

Some power saws, particularly jigsaws and circular saws, feature electronic speed control. This allows the user to adjust the speed of the saw depending on the material being cut, improving the precision of the cut and the longevity of the blade.

Laser Guides

Many power saws, especially miter saws, now come with built-in laser guides that project a visible line onto the wood. This feature helps users align their cuts more accurately, ensuring clean, precise results. Models such as the DeWalt DWS780 and the Bosch GCM12SD include this feature to enhance cutting accuracy.

Dust Collection Systems

Dust can quickly accumulate when cutting wood, making it difficult to see the workpiece and creating an unsafe work environment. Many modern saws come equipped with dust collection systems or ports that can be connected to a vacuum. This helps keep the workspace clean, improves visibility, and reduces health hazards from wood dust.

Anti-Kickback Systems

Kickback, where the saw blade suddenly moves backward due to resistance or a binding condition, is a common and dangerous occurrence in power saws. Many saws now feature anti-kickback mechanisms, including automatic brake systems, to stop the blade quickly if a kickback occurs. Safety-conscious brands like Bosch and DeWalt have integrated this feature in their products.

Tool-Free Adjustments

Many newer saw models offer tool-free adjustments, allowing users to make quick changes to the blade, depth, or bevel angle without the need for additional tools. This is a valuable feature for woodworkers who need to adjust their saws quickly during a project.

Power saws are powerful tools, and proper safety precautions should always be followed to prevent accidents and injuries. Here are some important safety tips for using power saws when cutting wood:

Always Wear Protective Gear

Safety glasses or goggles are essential to protect your eyes from flying debris. Hearing protection, such as earplugs or earmuffs, is also recommended, especially when using high-powered saws that generate loud noise. Additionally, wearing work gloves can help protect your hands from sharp edges and vibrations, and a dust mask can help prevent inhalation of harmful sawdust.

Follow Manufacturer Guidelines

Always read the user manual that comes with your saw. Understanding the proper usage, maintenance, and safety features of your saw will help prevent accidents. Familiarizing yourself with the saw’s capabilities will ensure that you use the tool correctly and within its intended limits.

Secure Your Workpiece

Always ensure that your workpiece is properly secured before cutting. Use clamps or a workbench to hold the wood steady, preventing it from shifting during the cut. An unstable workpiece can cause the saw to veer off course or bind, which may result in injury.

Keep Hands Away from the Blade

This is perhaps the most important safety tip: never place your hands near the blade while the saw is running. Always use the designated handles or grip points to guide the saw, and never attempt to clear wood from the cutting area while the saw is in motion.

Use the Right Blade for the Job

Make sure to use the appropriate blade for your specific cutting task. A fine-tooth blade is ideal for precision cuts, while a coarse-tooth blade is better suited for rough cutting. Choosing the right blade ensures smoother cuts and reduces the chances of the saw binding or stalling.

Inspect the Saw Before Use

Before starting a project, inspect the saw thoroughly. Check for loose parts, worn-out blades, or damaged cables. If you notice any issues, resolve them before using the saw to prevent malfunctions during operation.

Power saws are used in a wide variety of woodworking applications. Some of the most common uses include:

Rough Cutting

Circular saws and reciprocating saws are often used for rough cutting tasks, such as trimming large pieces of wood into more manageable sections. These saws are perfect for construction sites or demolition projects where speed and power are more important than precision.

Precise Crosscuts

For more precise cuts, table saws and miter saws are commonly used. Miter saws, in particular, are ideal for cutting wood at various angles, such as when creating frames or cutting moldings. The accuracy and consistency offered by these saws make them indispensable in fine woodworking.

Curved and Intricate Cuts

Jigsaws and band saws excel at making curved cuts and intricate patterns. Jigsaws, in particular, are often used in artistic woodworking projects, such as crafting decorative pieces or cutting out complex designs.

Resawing and Thicknessing

Band saws are often used for resawing, which involves cutting wood into thinner slabs. This is especially useful in woodworking where precise control over the thickness of a piece of wood is required, such as in furniture making or veneer production.

Cutting Wood for Framing

Miter saws and circular saws are both useful for cutting lumber for framing projects. These saws provide the necessary power and precision for making straight cuts, especially when working with large boards of lumber or plywood.

Power saws are essential tools in the woodworking industry, providing woodworkers with the precision, power, and versatility needed for a wide range of tasks. Whether you’re cutting through thick hardwood with a table saw, making intricate curves with a jigsaw, or performing quick rough cuts with a circular saw, the right saw can make all the difference. Leading brands such as DeWalt, Makita, Bosch, and Milwaukee offer a diverse range of saws, each with unique features that cater to different woodworking needs.

When choosing a power saw, it’s important to consider factors such as motor power, blade type, portability, safety features, and your specific cutting requirements. Regular maintenance, safety precautions, and the right accessories, such as blades and dust collection systems, can also extend the life of your power saw and ensure you achieve the best results with each project.

By investing in a high-quality power saw and using it correctly, woodworkers can enhance their efficiency and achieve professional-level results in their work. Whether you’re a professional contractor, a hobbyist, or a DIY enthusiast, power saws remain one of the most important tools in any woodworking shop.